Aircraft Parts Documentation, Traceability, and Condition Explained

Aircraft parts are not defined by part numbers alone. In practice, the usability, acceptance, and value of an aircraft component are determined by its documentation, traceability, and condition, and by how these elements align with regulatory and operational reality. Understanding this relationship is essential for operators, CAMOs, MROs, and asset owners.

In the aviation aftermarket, documentation is often discussed as a checklist item. In practice, documentation is the foundation that determines whether a part can be installed, repaired, sold, or even economically evaluated. A physically sound component without acceptable documentation may have limited or no operational value.

Documentation and traceability in practice

Traceability links a component to its origin, operational history, and regulatory context. This typically includes identification of the aircraft or engine from which the part was removed, installation position, removal date, and removal status. Traceability provides context, but it does not in itself constitute an airworthiness approval.

Acceptable documentation depends on the intended next use of the part. Some components may be suitable for evaluation and repair, others for direct installation, and others only for teardown or material recovery. In practice, documentation must be assessed against the intended pathway, not against an abstract standard.

At NEDAVION, documentation is reviewed conservatively. Where traceability is incomplete, limitations are stated clearly rather than inferred or implied. This protects downstream users and ensures that material is represented accurately.

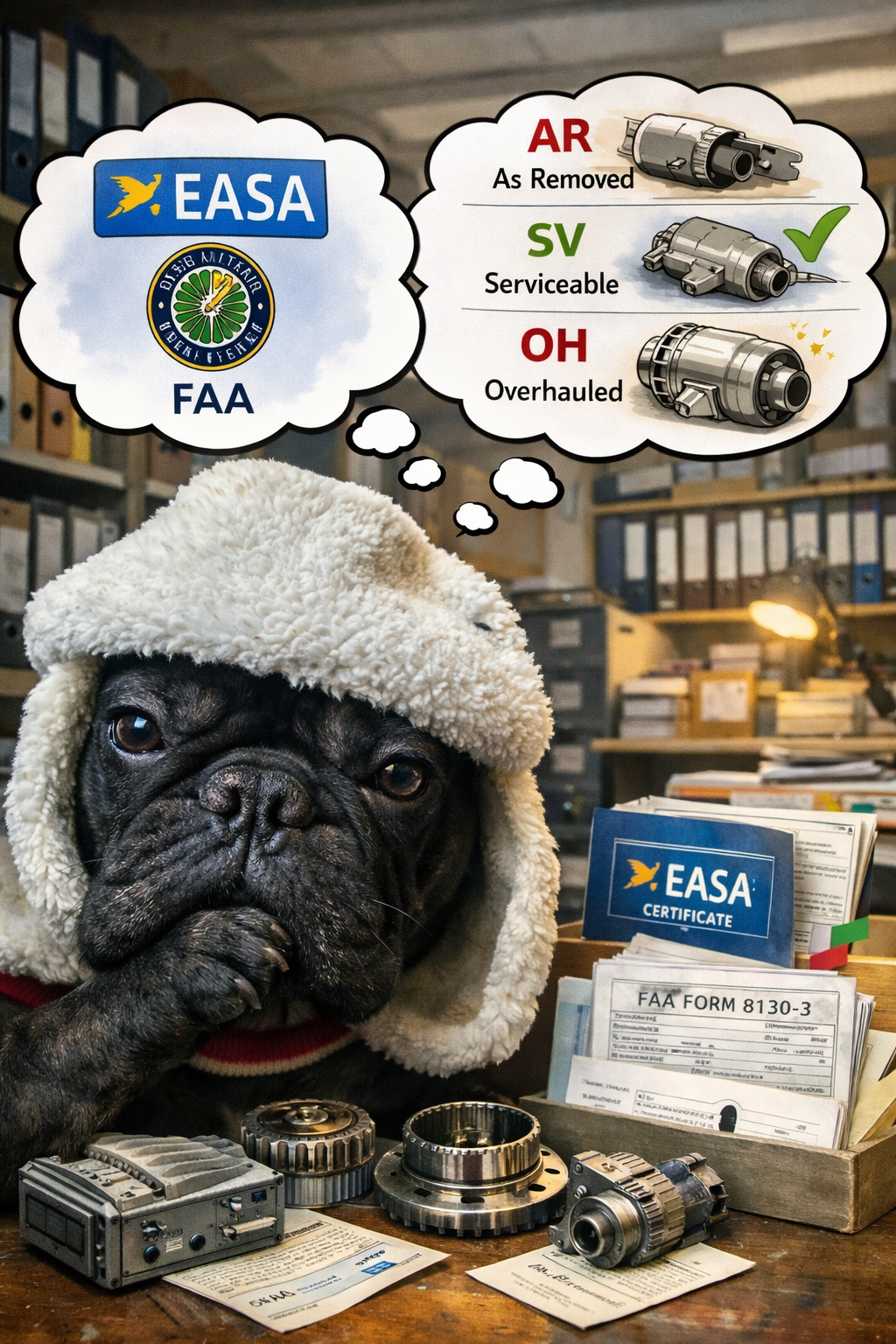

Certification and release documents

Airworthiness release documentation, such as EASA Form 1, FAA 8130-3, CAA Form 1, or equivalent, provides formal approval for installation or release. These documents are specific in scope and context. A release issued for one purpose does not automatically extend to all uses.